About मà¥à¤¨à¥à¤

ल à¤à¥à¤°à¥à¤µà¤¿à¤à¤ मशà¥à¤¨

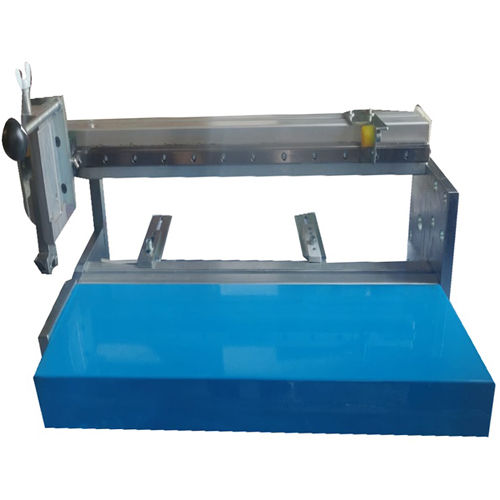

Manual Grooving Machine is an industrial unit that can be resorted to, especially when several operations must be made to cut and groove different materials. This portable, easy-to-use unit allows the operators to make repeatable grooves, thus, improving efficiency in manufacturing, woodworking, metal fabrication, and other fields. This machine utilizes variable settings for different groove sizes, ensuring adaptability depending on the nature of the projects involved. The manual operation of the Manual Grooving Machine gives users total control hence, the durable construction guarantees long life.

Key Features and BenefitsThis Manual Grooving Machine is engineered for robust industrial tasks, marrying manual control with the efficiency of an automatic feeder and electric drive. Despite its advanced features, operation remains non-automatic, giving users direct oversight of the process. The machines durable build, blue and gray design, and a 1-year warranty distinguish it from competitors, making it a trusted asset in manufacturing settings.

Industrial ApplicationsIdeal for various industrial sectors, this grooving machine handles a wide range of materials, enabling precise creation of grooves necessary for assembly, fitting, or design requirements. The automatic feeder aids in continuous operation, boosting productivity, especially in settings where consistency and reliability are paramount.

FAQs of Manual Grooving Machine:

Q: How does the automatic feeder function in this manual grooving machine?

A: The automatic feeder steadily moves the material through the machine, ensuring grooves are applied uniformly and efficiently, while still allowing the operator manual control over the grooving process.

Q: What are the advantages of using a non-computerized, electric drive system for industrial grooving?

A: A non-computerized, electric drive system offers simplicity and reliability. Theres less risk of digital malfunction, making it ideal for environments where straightforward operation and minimal maintenance are valued.

Q: When should the Manual Grooving Machine be serviced during its warranty period?

A: For optimal performance, it is recommended to follow manufacturer guidelines for periodic servicinggenerally every six months or as advised in the manualespecially within the one-year warranty term.

Q: Where is this grooving machine manufactured and supplied?

A: This Manual Grooving Machine is manufactured and supplied by a trusted provider in India, ensuring local service support and adherence to industry standards.

Q: What is the process for operating the machine safely in an industrial environment?

A: To operate the machine safely, ensure the electric drive is properly connected, set up the material in the automatic feeder, and monitor the grooving action while maintaining safety protocols such as wearing appropriate protective gear.

Q: What are the primary benefits of using this grooving machine in industrial applications?

A: Key benefits include increased productivity due to the automatic feeder, precise manual control, robust construction, and peace of mind provided by the one-year warranty, making it highly suitable for industrial grooving tasks.