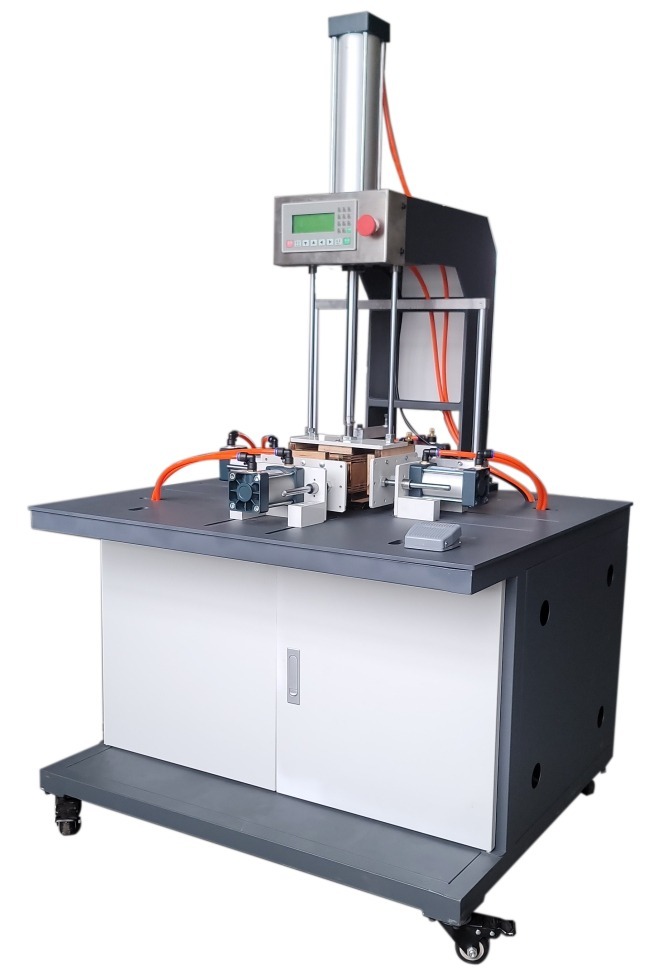

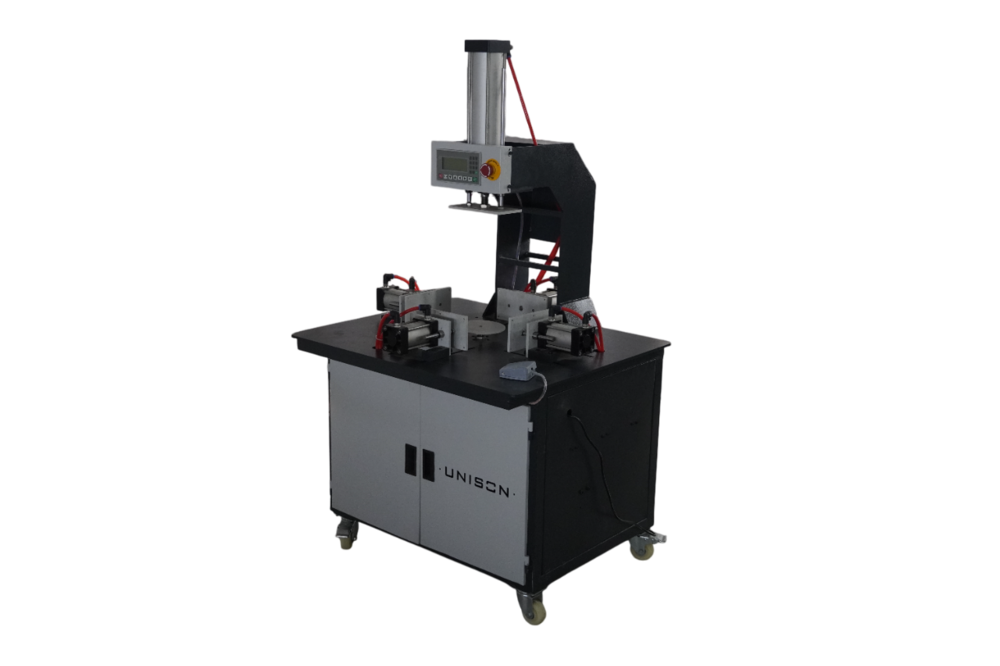

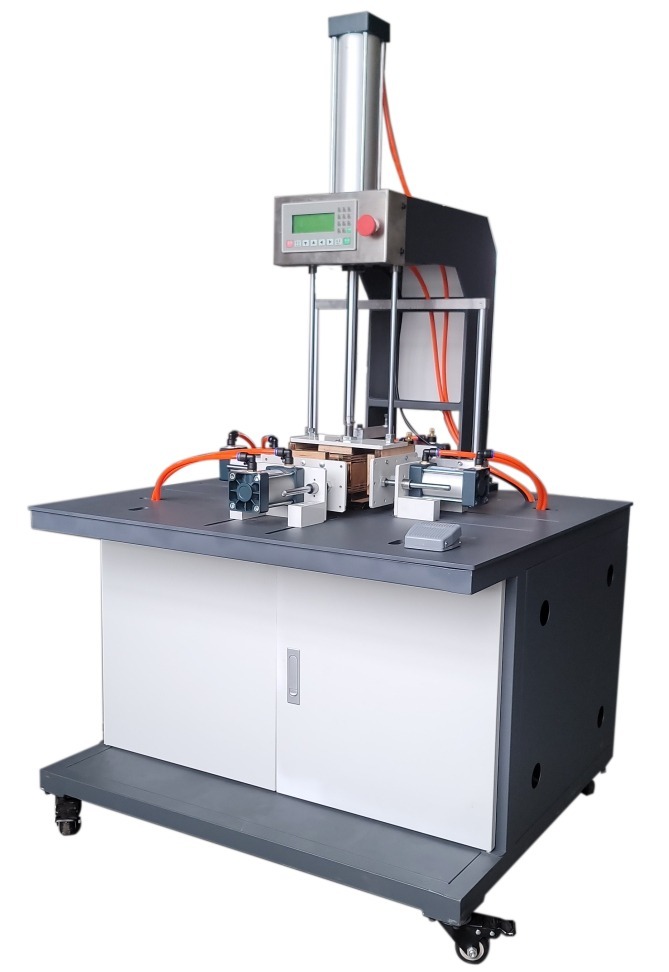

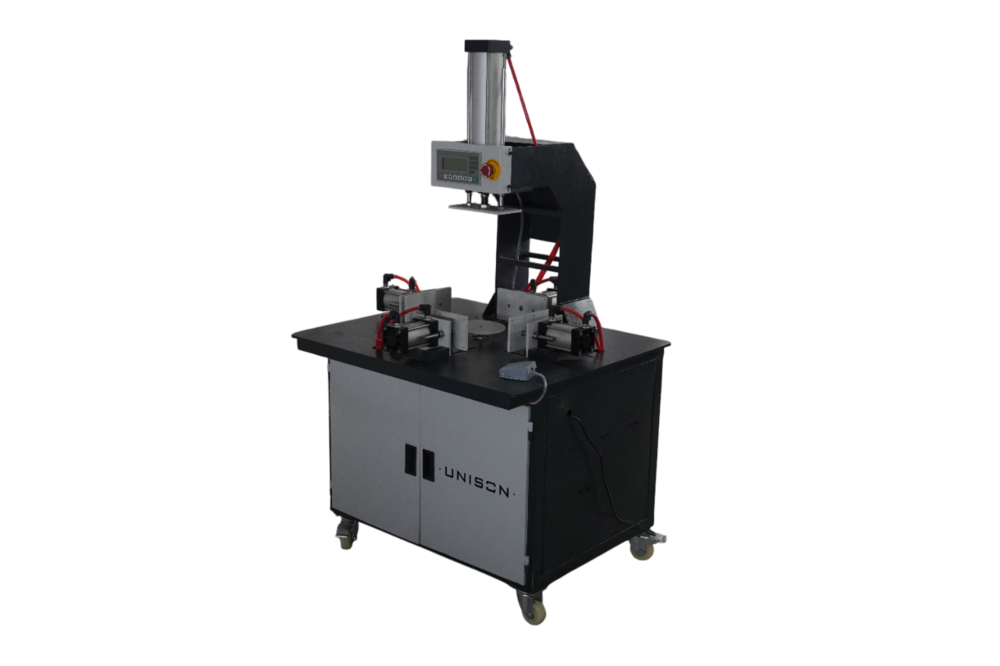

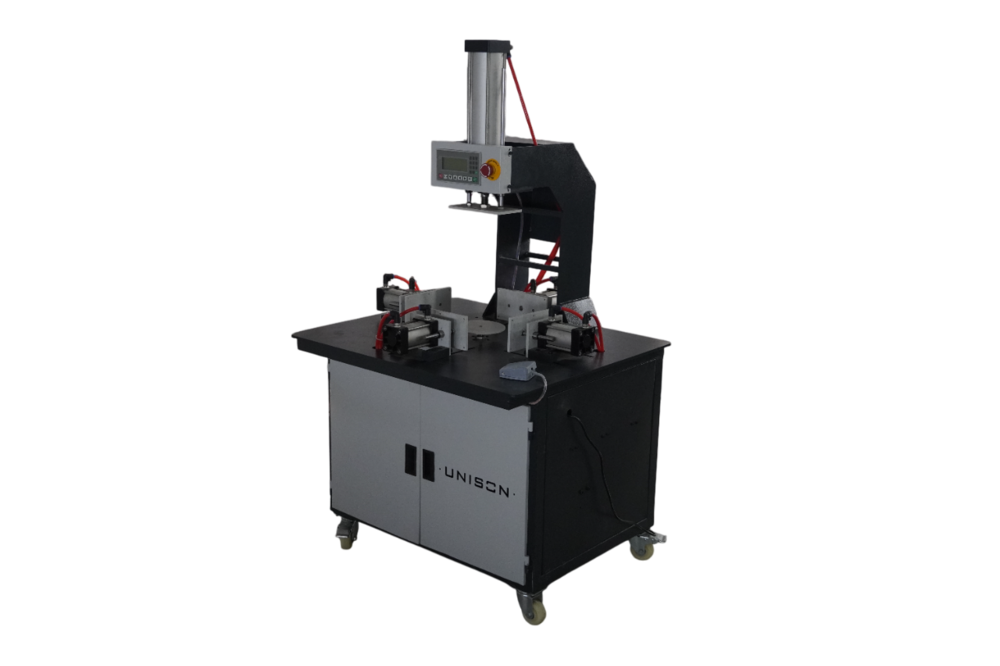

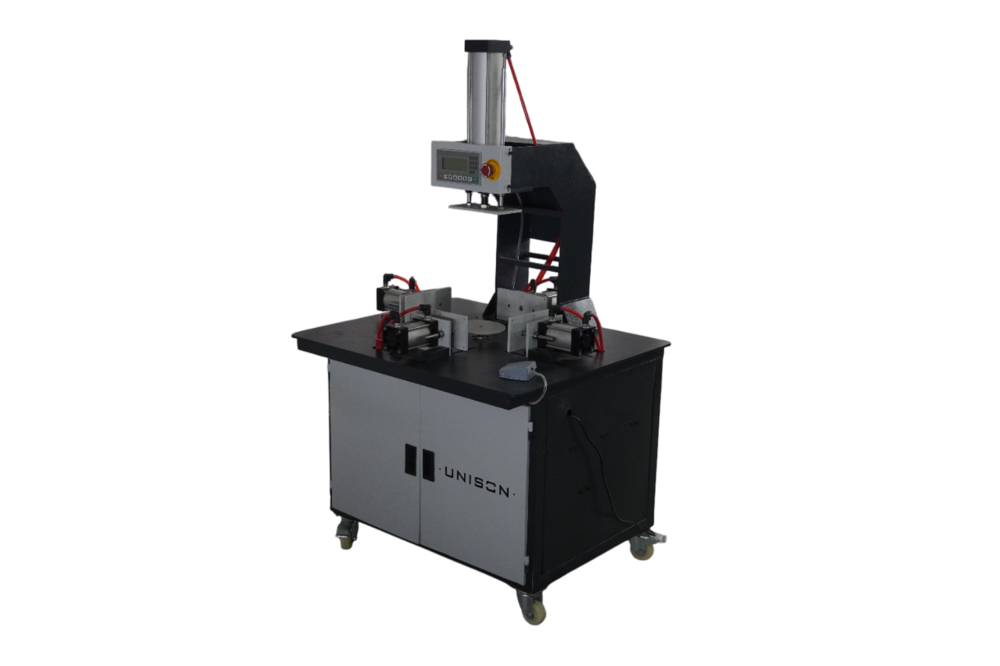

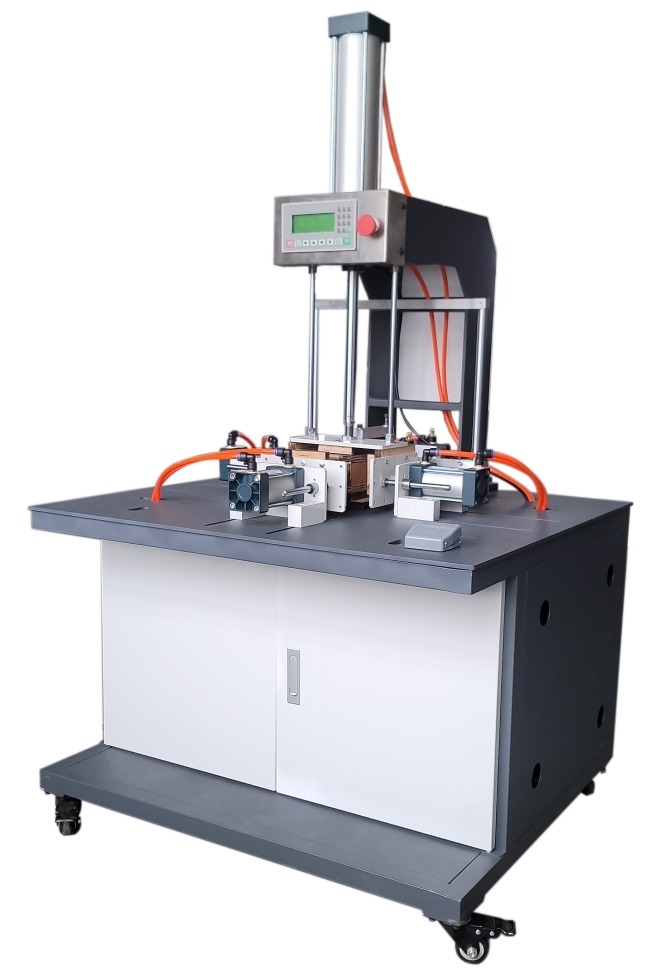

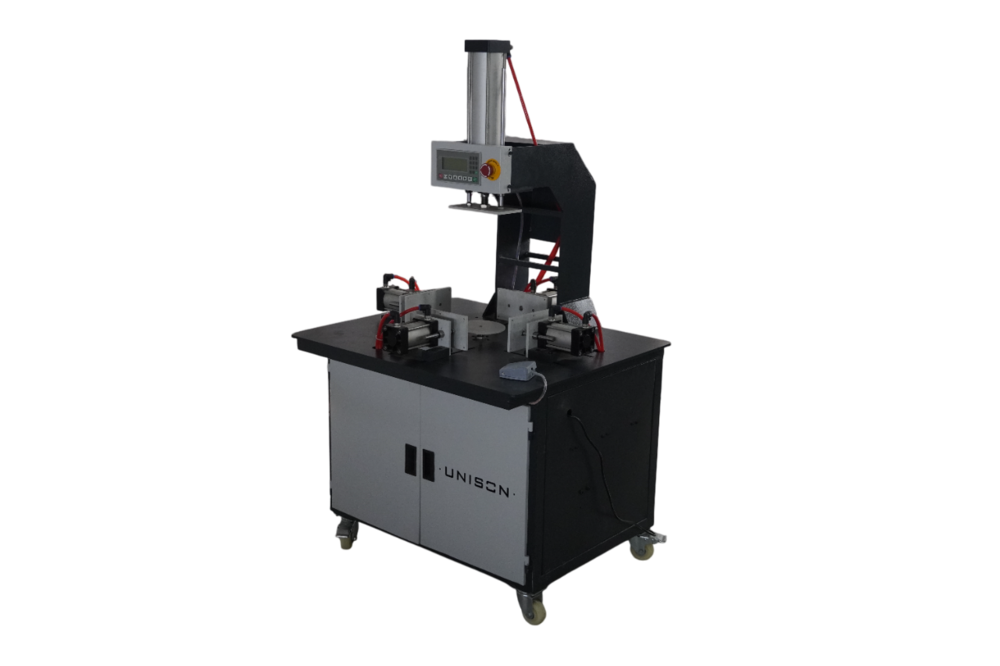

About Bubble Pressing Machine

Bubble Pressing Machine streamlines the process of creating rigid boxes owing to the efficient application of bubble-free adhesion- ultimately, this ensures that the glue attaches the sheets to the pressure to bubble effectively. It has adjustable options and an easily operated interface, which would give it higher productivity during the manufacturing process and reduction of waste. The Bubble Pressing Machine is a must-have tool in rigid box making processes which has been developed to provide consistently high-quality results for packaging professionals, an investment worthwhile modern packaging companies should make.

High-Efficiency Industrial PerformanceThis Bubble Pressing Machine delivers exceptional productivity for industrial applications. Its automatic operation and reliable electric drive reduce manual workload and boost output consistency. Suitable for handling paper materials, it enhances product quality while keeping operational demands low.

User-Friendly and Reliable OperationDespite being non-computerized, the machine is easy to use and maintain. Clear, accessible controls allow operators to quickly manage tasks and make necessary adjustments with minimal training. Its robust build ensures durability and longevity in demanding production settings.

FAQs of Bubble Pressing Machine:

Q: How does the Bubble Pressing Machine operate?

A: The Bubble Pressing Machine works automatically with an electric drive, pressing paper materials into desired shapes and structures. Operators simply load the paper material, set the required parameters, and initiate the automatic cycle for consistent and efficient bubble pressing.

Q: What materials can the Bubble Pressing Machine process?

A: This machine is specifically engineered for processing paper materials, making it suitable for various paper-based industrial applications such as packaging, cushioning, and protective product manufacturing.

Q: When is it ideal to use this machine in industrial settings?

A: It is best utilized in production lines requiring continuous, high-volume bubble pressing tasks. Its automatic functionality and wide voltage range make it suitable for both medium and large-scale manufacturing operations.

Q: Where is the Bubble Pressing Machine manufactured and supplied?

A: The machine is manufactured and supplied in India, ensuring it is tailored to the requirements and standards of Indian industrial environments.

Q: What is the process of using the Bubble Pressing Machine?

A: To use the machine, operators load the paper material, set the operational parameters, and then start the automated process. The machine performs the pressing operation automatically, resulting in uniformly shaped products.

Q: How does this machine benefit industrial manufacturers?

A: It streamlines production by automating the bubble pressing process, significantly reducing manual labor. Manufacturers benefit from improved efficiency, consistent product quality, and the ability to handle large quantities with ease.